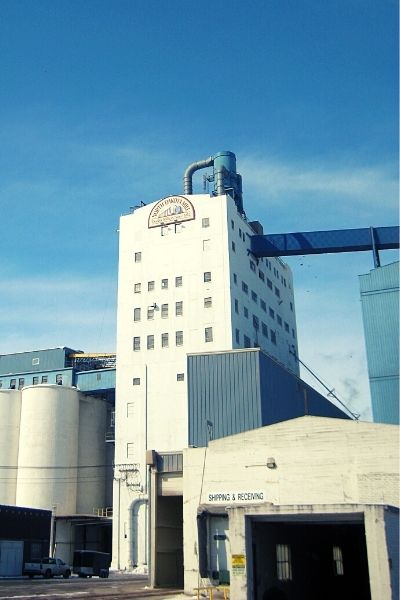

North Dakota Mill is taking no chances: it has entrusted Ocrim with the construction of two new milling plants and the renewal of an existing one. A complex project that focuses on sanitation, renovation and energy saving requirements, and which must be in operation within a very short deadline. The collaboration between the two companies dates back to 1980; all these years later, the largest mill in North America still reconfirms its trust in Ocrim’s professional and technological abilities.

Only a few months to go before the one hundred years of activity come full circle. The North Dakota Mill and Elevator Association was founded in 1922 to promote the local economy and lend support to the area’s farmers. At the time, wheat was sent to grinding structures in Minneapolis. The sale terms and conditions, in a system that had all the markings of a monopoly, and the high transport costs significantly lowered revenue, creating serious economic difficulties for the entire farming sector. The problem was solved by creating the first and only state-owned milling plant in the United States, in Grand Forks. An inspired decision that gave a great boost to the entire industrial and trade sector – and, by extension, to the economy – of North Dakota. Nowadays, with eight milling plants, the mill produces and ships over 2,240 T of flour and 635 T of bran per day, making a sizeable contribution to the State’s economy. In order to produce higher levels of profit, the North Dakota Mill marches, at a brisk pace, towards new development targets, adopting marketing strategies that include the production of excellent flours for bread-making, the development of new products and their retail trade. Hence they need the structure to be expanded with new plants, whose design and construction they, once again, entrusted to Ocrim.

Ocrim Is Already On It

There’s not a minute to lose: the customer needs the project delivered as soon as possible and the Ocrim team is already on the case. They are called to construct two new milling plants and renovate an existing one: the two new durum and hard mills, H and I, will have a capacity of 360 T/D and 250 T/D, respectively. The existing durum wheat mill D is going to be converted and adapted to also process common hard wheat, with increased capacity and the integration of the most recent Ocrim machines. The final design will also include the installation of a cutting-edge energy saving system to optimise consumption.

“We opted for Ocrim because it has always proven to be a loyal and understanding partner”, said Vance Taylor, president and CEO at North Dakota Mill. “We asked for very short delivery times and Ocrim accepted the challenge, precisely because it is aware of its own organisational, managerial and strategic abilities. Skills that have also been tested during the current severe pandemic. Together we have already overcome many challenges and we, at North Dakota Mill, are thrilled to once more go down the Italian route.”