Taylor-made handling systems for products packaging and palletizing are taylor-made and appealing exactly like milling plants. This is what emerges from important orders in Italy and abroad.

Ocrim’s focus on the Italian Made is rewarding: it worths the efforts, the commitment and the passion put in place to support a technological, innovative and sustainable strategy aimed to increase an entire Italian production. One of the latest goals concerns mill logistics, which is actually the product packaging and palletizing. These passages are the final step of the process, a missing piece in Ocrim agri-food chain: this is the reason why Ocrim acquired FBC of Medesano (Parma-Italy) in 2017. FBC is an historical Italian company that has always been designing and building handling systems since 1980. It is specifically focused on bags, bundles and other packaging palletizing.

More than 1,600 mechanical and robotic installations were carried out in different production sectors all over the world: starting from milling, to chemical, inert, plastics industry and so on. The partnership with Ocrim was confirmed in 2017 thanks to the creation of a “business unit”: the aim is to offer the customers also the final passage in the production chain. Generally, at least three orders a month are fulfilled thanks to the engineering skills and FBC long experience in solving, turnkey, palletizing and winding issues.

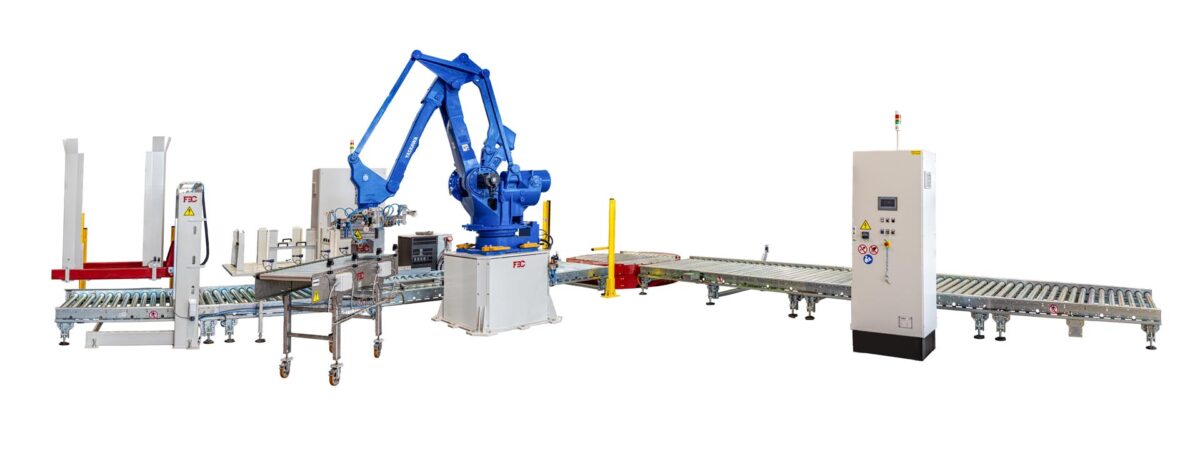

Handling systems are located downstream the production line, where the product is packaged in the primary packaging and the goods are palletised. This is a crucial step from a logistics point of view: in order to maximize the payback and not losing efficiency in milling plants, the handling system needs to be designed properly. OCRIM/FBC can offer a taylor-made and flexible solution for each company, adapting the installation to the existing line: the latest handling systems designed for Molinos de Costa Rica and Harinero Sula are proof of this. Right for this last one, Ocrim has provided an optimal solution despite a very complex starting situation. The robot installation has been quite difficult because of the characteristics of the product itself (bundles of impalpable flour) but, thanks to OCRIM/FBC technicians’ mindful and wise studies, the issue was solved by designing a specific gripping system.

Pasini Mill Choses Ocrim

In an interview Roberto Cagna, OCRIM/FBC handling systems manager, stated how difficult and demanding customized a plant can be. He took as example the installation of a robotic palletizing plant for 1 and 1/2 kg bundles of flour or baking mixtures for Molino Pasini, a renowned milling company in Cesole (Mantua, Italy). The plant itself is simple and standard, but the customer’s needs and the context in which the handling system was inserted required a unique design in order to be managed efficiently. In addition to the customer request, the automation software was designed to manipulate the robot gripping system: this way the robot can automatically insert paper interlayers on the empty pallet and between the layers of bundles. As a consequence, the risk to damage the product decreases and, at the same time, the load is stabilized. To sum up, Molino Pasini is able to look to the future by setting up an “open” thanks to OCRIM/FBC expertise: the upgraded plant will be able to achieve higher productive and economic benefits.